Views: 0 Author: Site Editor Publish Time: 2025-11-05 Origin: Site

You often need to pick between bow shackles and d-shackles when you use lifting or rigging gear. The main difference is their shape and how they hold weight. Knowing this helps you choose safely and easily. For example:

Bow shackles are good when you have many connections or loads from different sides.

Dee shackles are better in small spaces and for straight pulls.

Choosing the right shackle keeps your gear safe, gives enough strength, and makes sure you use the best tool for the job.

Bow shackles are great for joining many slings. They can hold loads from different sides.

Dee shackles work best for straight pulls. They fit well in small spaces.

Always look at the working load limit on your shackles. This helps keep lifting safe.

Pick the right shackle type for your project. This stops accidents and keeps equipment safe.

Check shackles for wear and damage before using them. This helps keep things safe and reliable.

Bow shackles are important for lifting and rigging jobs. They have a round shape, like an arch or bow. This shape lets you connect many slings or ropes at the same time. Bow shackles can hold weight from different sides. This makes them useful for lots of tasks. People use bow shackles in shipping, construction, and mining. They work well when loads move or come from an angle.

Tip: Bow shackles work best if you need to attach more than one lifting point or if the load might shift.

Here is a simple table to compare bow shackles and d-shackles:

Shackle Type | Shape | Characteristics |

|---|---|---|

Bow Shackle | Rounded | Good for loads from many directions, used in lots of rigging jobs. |

Dee Shackle | D-shaped | Has a narrow bow, made for straight pulls, not for side loads. |

Rules like ISO 2415 and ASME B30.26 set tough standards for bow shackles. These rules say how much weight shackles can hold, from 0.5 tons to 120 tons. They also list grades 6, 8, and 10, and temperature limits from -20°C to 200°C. Shackles that meet these rules work well and fit with other rigging gear.

Dee shackles, or d-shackles, have a straight and narrow shape. They look like the letter "D." You use dee shackles for pulling or lifting in a straight line. Their shape keeps the load in the middle and stops twisting. Dee shackles are best for small spaces or when you need a strong, direct link.

D-shackles should not be used for side pulls. They are strongest when used for straight pulls. Many jobs use d-shackles for lifting, hoisting, and holding loads.

Bow shackles and dee shackles are made from stainless steel, carbon steel, and alloy steel. Stainless steel is special because it does not rust, is very strong, and lasts a long time. It needs less care and works better, especially outside or near water.

If you want safe shackles, Hebei Anyue Metal Manufacturing Co., Ltd. makes products that follow world standards and pass hard tests. You can trust their bow shackles and d-shackles for your next job.

When you look at lifting hardware, you notice that bow shackles and dee shackles have unique shapes. These shapes affect how you use them and how safe your rigging setup is. Understanding the shape and design differences helps you choose the right shackle for your job.

Bow shackles have a large, rounded body. This design creates a wide loop, which lets you attach several slings or ropes at once. The curved shape spreads the load across a bigger area. You get more flexibility because the shackle can handle forces from different directions and angles. This is important when the load might shift or move.

Bow shackles work well in crane operations and bridge construction. You can connect the hoist to the load and avoid putting too much stress on one spot.

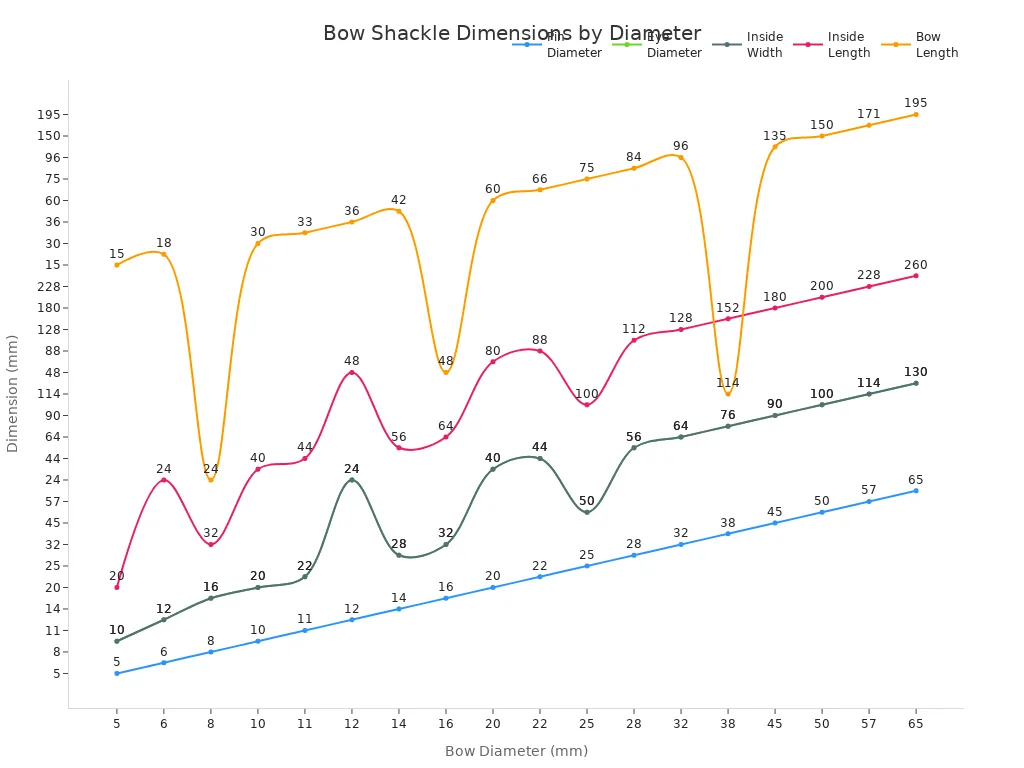

Here is a table showing typical dimensions for bow shackles:

Bow Diameter (mm) | Pin Diameter (mm) | Eye Diameter (mm) | Inside Width (mm) | Inside Length (mm) | Bow Length (mm) | Approx. Weight per 100 Pieces (kg) |

|---|---|---|---|---|---|---|

5 | 5 | 10 | 10 | 20 | 15 | 1.54 |

6 | 6 | 12 | 12 | 24 | 18 | 2.66 |

8 | 8 | 16 | 16 | 32 | 24 | 6.29 |

10 | 10 | 20 | 20 | 40 | 30 | 12.3 |

12 | 12 | 24 | 24 | 48 | 36 | 21.2 |

16 | 16 | 32 | 32 | 64 | 48 | 50.3 |

22 | 22 | 44 | 44 | 88 | 66 | 131 |

32 | 32 | 64 | 64 | 128 | 96 | 403 |

50 | 50 | 100 | 100 | 200 | 150 | 1,536 |

You see bow shackles used in ship shipping, mining, and power construction. Hebei Anyue Metal Manufacturing Co., Ltd. makes bow shackles that meet ISO 9001 and CE standards. Every shackle goes through spectral testing, hardness testing, and load testing. You get reliable products with a 6:1 release the shackle safety factor.

Dee shackles have a straight, narrow body. The shape looks like the letter "D." You use dee shackles for straight pulls. The design keeps the load steady and prevents side loading. This makes them perfect for tight spaces or when you need a strong, direct connection.

Here is a table comparing bow shackles and dee shackles:

Feature | Bow Shackles | Dee Shackles |

|---|---|---|

Shape | Larger, rounded shape suitable for multiple slings | More angular, resembling a chain for straight pulls |

Load Handling Direction | Can handle loads in various directions and angles | Best for loads moving in one direction only |

Stability | Remains strong even if load is not centered | Prevents side loading, better for controlled lifts |

You find dee shackles in engineering hoisting and stage machinery. The straight design helps you keep the load stable. Hebei Anyue Metal Manufacturing Co., Ltd. produces dee shackles that follow ASME and OSHA standards. Each shackle has a working load limit (WLL), manufacturer’s mark, and batch ID for safety. You get products that pass regular inspections and meet strict quality requirements.

Tip: Always check your shackles for wear, corrosion, or damage before use. This keeps your rigging safe and reliable.

Bow shackles distribute loads over a larger area, reducing stress on each part.

Dee shackles keep the load steady and direct, which helps in controlled lifts.

Both types help you transfer weight and avoid putting too much force on one spot.

If you want custom solutions, Anyue offers CAD design services and free technical consulting. You can request hot-dip galvanized shackle, electroplated zinc shackle, or G209 shackle options to match your project needs. Many users trust Anyue for safe, certified shackles. You can contact their team for expert advice and fast delivery.

Bow shackles are helpful when you need flexibility. Their rounded shape lets you attach slings or ropes at different angles. You can connect many lifting points at once. The forces spread out across the shackle. This helps protect your gear from damage. Bow shackles work well in tricky lifts where loads might move. They are strong and safe for jobs that need flexibility. You can use them in ship shipping or construction. Sometimes, you need to lift things that do not stay still. Bow shackles make these jobs easier and safer.

The rounded body lets you connect more than one lifting point.

Forces spread out, so your gear stays safe.

Bow shackles are good for lifts where loads might shift.

Tip: Always check the working load limit before using a shackle. Hebei Anyue Metal Manufacturing Co., Ltd. offers hot-dip galvanized shackle, electroplated zinc shackle, and G209 shackle choices. These shackles meet tough safety rules and have a 6:1 safety factor.

Dee shackles are best for straight pulls or lifts. Their straight, narrow shape keeps the load steady. You should use dee shackles when the force goes in one direction. Dee shackles are made for straight tension across the pin. If you pull from the side, the shackle gets weaker. For example:

0 to 5 degrees: No strength loss.

6 to 45 degrees: 30% less strength.

46 to 90 degrees: 50% less strength.

Over 90 degrees: Not safe to use.

Do not use dee shackles for side or angled pulls. Only anchor shackles can handle side loads, but you must lower the rated load as the maker says. Dee shackles work well for careful lifts, like in engineering or stage setups.

Note: Always follow the maker’s rules for load direction and flexibility. This keeps your rigging safe and helps stop accidents.

It is important to know how much weight bow shackles can hold. Makers set limits based on the size and what they are made of. Bow shackles made from alloy steel or stainless steel are very strong. They are good for heavy jobs. You can see the differences in this table:

Shackle Type | Working Load Limit | Material |

|---|---|---|

Heavy Duty Bow Shackle | 200 tons | Alloy steel, Grade 8, quenched and tempered |

Screw Pin Bow Shackle | 2.50 tons (5000 lbs) | Type 316 Stainless Steel |

Bow shackles let you lift from many directions. You can use them in ship shipping, mining, and building work. Hebei Anyue Metal Manufacturing Co., Ltd. checks every shackle for strength and safety. Their shackles meet ISO 9001 and CE rules. You can pick hot-dip galvanized shackle, electroplated zinc shackle, or G209 shackle. Each shackle has a 6:1 safety factor. This means you can trust your gear for hard jobs.

Tip: Always look at the working load limit on your shackle before lifting. This keeps your team and tools safe.

Dee shackles, also called d-shackles, have a small and tight shape. This helps them handle straight pulls with high strength. Dee shackles work best in small spaces and for direct links. You can use them for lifting in engineering or stage setups.

Bow shackles are good for heavy lifts and loads from many sides.

Dee shackles are used for lighter jobs needing straight pulls.

D-shackles can carry a bit more weight because of their shape.

Bow shackles are usually stronger than d-rings of the same size.

Bow shackles are best for many connections and spreading out weight.

Dee shackles fit better in small spaces and direct links, and can handle more weight with their compact shape.

You can choose the right load capacity for your project. Hebei Anyue Metal Manufacturing Co., Ltd. has many sizes and materials. Their shackles pass three safety checks and meet tough safety rules.

Note: Always pick the right shackle for your lifting job. This helps stop accidents and keeps your rigging safe.

When you pick a shackle, think about the pin type. The pin keeps things safe and makes the shackle easy to use. Bow shackles and dee shackles have two main pin types. These are screw pins and bolt types. Each pin type works best for certain jobs.

Screw pin shackles are quick to set up. You twist the pin in by hand. This is good when you need to connect and disconnect often. Use screw pin shackles for short lifts, towing, or stage rigging. The pin stays tight, but check it before each lift.

Common features of screw pin shackles:

Fast to put on and take off

Simple design makes checking easy

Good for short or changing connections

You can find screw pin options in Hot-dip galvanized shackles, Electroplated zinc shackles, and G209 shackles from Hebei Anyue Metal Manufacturing Co., Ltd. These shackles follow strict safety rules and have a 6:1 Release the shackle safety factor. They work well for daily rigging jobs.

Tip: Always tighten the screw pin all the way before lifting. Look at the pin for damage or wear to keep your rigging safe.

Bolt type shackles use a bolt, nut, and split pin to lock things in place. You need tools to set them up, but they are extra safe. Bolt type shackles are best for jobs that last a long time. You see them in heavy lifting, big hoisting, and places where safety is very important.

Advantages of bolt type shackles:

Very safe for important lifts

Less chance of coming loose by accident

Best for jobs that stay in place

You can get bolt type shackles in Hot-dip galvanized shackle, Electroplated zinc shackle, and G209 shackle models. Hebei Anyue Metal Manufacturing Co., Ltd. checks every shackle for strength and safety. Their shackles pass three tests and meet ISO 9001 and CE rules.

Pin Type | Ease of Use | Security Level | Best Use Case |

|---|---|---|---|

Screw Pin | Very easy | Good | Temporary connections |

Bolt Type | Needs tools | Excellent | Permanent connections |

Note: Pick bolt type shackles for jobs that stay in place. Use screw pin shackles when you need to change things quickly.

If you want help, you can talk to Anyue’s team for free advice and samples. You get safe, certified shackles for every rigging job.

Bow shackles are used in jobs that need strength and flexibility. Their round shape lets you connect many slings or ropes. This helps when lifting loads that might move or come from different sides. Bow shackles are used in lots of places:

Construction: You lift beams and heavy tools.

Transportation: You hold cargo and link chains.

Marine and offshore energy: You anchor ships and handle mooring lines.

Mining: You move big rocks and machines.

Power and utilities: You lift transformers and cables.

Oil and gas: You rig pipes and heavy tools.

Agriculture and forestry: You tow gear and lift logs.

Entertainment: You set up stage rigging and lights.

Bow shackles are good for moving cargo and building things. They work well because they can handle loads from many angles. You can pick Hot-dip galvanized shackle or Electroplated zinc shackle to stop rust. Hebei Anyue Metal Manufacturing Co., Ltd. has bow shackles in many sizes, colors, and finishes. You can ask for special colors like black or red. Our bow shackles meet CE and ISO rules and have a 6:1 Release the shackle safety factor. You can also get G209 shackle models for special jobs.

Tip: Bow shackles are best if you need to lift from more than one direction. They give you safety and flexibility.

Dee shackles, or d-shackles, have a straight and narrow shape. You use them for jobs that need a strong, direct link. Dee shackles work best when the force goes in one direction. You see them used for:

Rigging: You connect lifting slings and chains.

Lifting: You lift loads in a straight line.

Towing: You attach tow ropes and cables.

Tie-downs: You secure loads on trucks and trailers.

Hoisting: You lift gear in safe places.

Pulling: You move things with steady force.

D-shackles fit well in small spaces and are strong for straight pulls. Hebei Anyue Metal Manufacturing Co., Ltd. lets you pick custom dee shackles for your project. You can choose the finish and size you need. Our d-shackles pass tough safety checks and meet world standards.

Here is a table that shows how our bow shackles and dee shackles compare:

Feature | Bow Shackles | Dee Shackles |

|---|---|---|

Customization Options | Available in black, red, and custom colors | Support customization based on customer needs |

Certifications | CE/ISO Certified | CE/ISO Certified |

Surface Treatment | Galvanized for corrosion resistance | Galvanized for corrosion resistance |

Size Range | From 0.5t to 55t | Wide range available |

Note: You can talk to our team for free advice and samples. We help you pick the right shackle for lifting, towing, or rigging.

When you pick a shackle for lifting or rigging, you need to think about a few things. You want your team to stay safe and your gear to work well. Here are the main points to remember:

Application Requirements: Check what your project needs. Think about how much weight you will lift, how much space you have, and how you will attach the shackle.

Working Load Limit (WLL): Pick a shackle that can hold more than your heaviest load. This helps keep everyone safe.

Load Direction: Bow shackles are best if the load comes from different sides. Dee shackles work better for straight pulls.

Space Constraints: Dee shackles fit in small spaces. Bow shackles are good for bigger setups.

Environmental Factors: If you work outside or near water, use stainless steel for rust protection. Galvanized shackles help stop rust in less tough places.

Ease of Use: Make sure your shackle fits with other gear. Screw pin shackles are easy for short jobs. Bolt-type shackles are best for jobs that last a long time.

Standards Compliance: Look for shackles that meet safety rules like ASME B30.26 or EN 13889. Hebei Anyue Metal Manufacturing Co., Ltd. sells certified Hot-dip galvanized shackle, Electroplated zinc shackle, and G209 shackle.

Factor | Recommendation |

|---|---|

Shackle Type | Bow for loads from many sides; Dee for straight pulls |

Material | Stainless steel for rust; Alloy steel for strength; Galvanized for general use |

Pin Type | Screw pin for short jobs; Bolt-type for long jobs |

Inspection | Check for damage, wear, and marks before using |

Tip: Always look at your shackles before you use them. Make sure the pin fits tight and the shackle does not show rust or damage.

You should try not to make mistakes that can break your gear or hurt someone. Here are some common errors people make with shackles:

Using the wrong shackle for the job

Not checking gear before using it

Not looking at the weight and strength of the load

Using the wrong sling or hitch for the job

Ignoring the shackle’s working load limit

These mistakes can break your gear, make you lose control when lifting, or cause injuries. Always check your shackle’s strength and make sure it fits your job. Look at your shackles for noise, bad alignment, wear, rust, or bending. Keep shackles dry and clean them often to stop rust.

Note: If you need help picking a shackle, talk to Hebei Anyue Metal Manufacturing Co., Ltd. for free advice and samples. Your safety depends on making the right choice.

Bow shackles and dee shackles work in different ways. Bow shackles can handle loads from many directions. Dee shackles are best for straight pulls. The table shows what makes each type special:

Feature | Bow Shackles | Dee Shackles |

|---|---|---|

Load Direction | Multi-directional | Straight-line |

Flexibility | High | Controlled lifts |

Applications | Construction, transport | Industrial, towing |

Pick the right shackle by checking your gear first. Look at the working load limit before you use it. Make sure the shackle matches your job. If you need help, you can ask Hebei Anyue Metal Manufacturing Co., Ltd. They give advice and help you stay safe.

You see bow shackles with a rounded shape. Dee shackles look like the letter "D." Bow shackles handle loads from many directions. Dee shackles work best for straight pulls.

You use a Hot-dip galvanized shackle when you need extra protection against rust. This shackle works well outdoors or near water. It lasts longer in harsh environments.

You see "6:1 Release the shackle" on certified shackles. This means the shackle can hold six times its working load limit before breaking. You get extra safety for lifting jobs.

You pick a screw pin shackle for quick, temporary jobs. You choose a bolt type shackle for permanent or long-term connections. Bolt type shackles offer more security.

You get shackles that meet ISO 9001 and CE standards. Every product passes three safety tests. You can request free samples and expert advice for your project.